Purchasing Your First 3D Printer

Welcome to the captivating world of 3D printing! Whether you’re a budding inventor, an avid hobbyist, or simply curious about this transformative technology, this guide will provide you with in-depth knowledge, concrete examples, and actionable advice to navigate the vast landscape of 3D printers and make an informed purchase for your first 3D printer.

I. Understanding 3D Printing: Laying the Groundwork

A. What is 3D Printing?

3D printing is an additive manufacturing process that creates objects by building them layer by layer from a digital design. Imagine sculpting a statue not by removing material from a block of stone but by successively adding tiny layers until the final shape emerges. This method enables the production of complex geometries that would be nearly impossible to achieve through traditional subtractive methods.

Real-World Example:

Consider how aerospace companies prototype parts. Instead of spending weeks carving a component out of metal, engineers design a part using CAD software and print it in a few hours. This not only speeds up the prototyping process but also allows for intricate internal structures—such as lattice supports—that reduce weight without sacrificing strength.

B. The Journey from Digital to Physical

The process begins with creating a 3D model using computer-aided design (CAD) software. The model is then “sliced” into thin horizontal layers by specialized software known as a slicer. The 3D printer interprets these slices to deposit material layer by layer until the complete object is formed.

Real-World Example:

A designer creating custom phone cases will model the design in CAD software, slice it to determine optimal layer height and infill density, and finally print a prototype. Adjustments can be made easily in the digital model before printing a final version that fits perfectly.

C. Key 3D Printing Technologies for Hobbyists and Makers

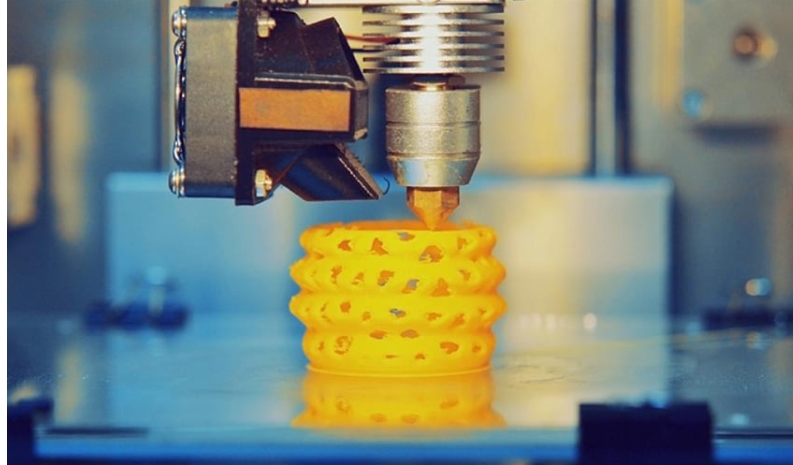

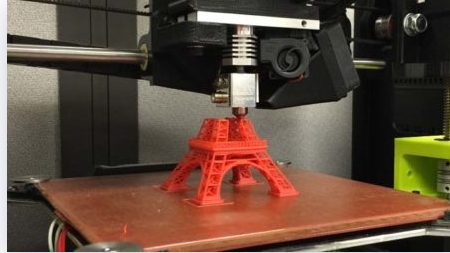

Fused Deposition Modeling (FDM)

- How It Works: FDM printers heat a thermoplastic filament (like PLA, ABS, or PETG) and extrude it through a nozzle to create each layer.

- Pros:

- Widely available and affordable

- Supports a diverse range of materials

- Ideal for printing larger, functional parts

- Cons:

- Layer lines may be visible, necessitating post-processing (sanding or smoothing)

- Precision may be limited compared to other methods

Real-World Example:

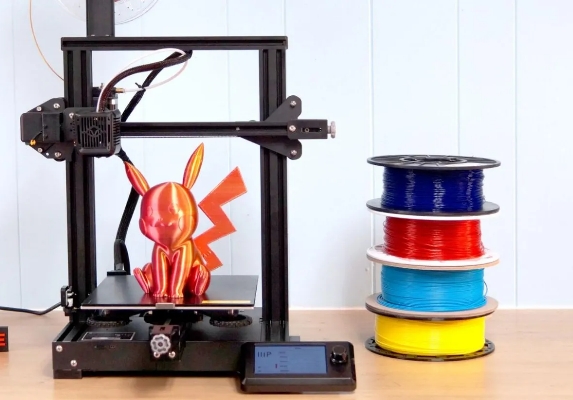

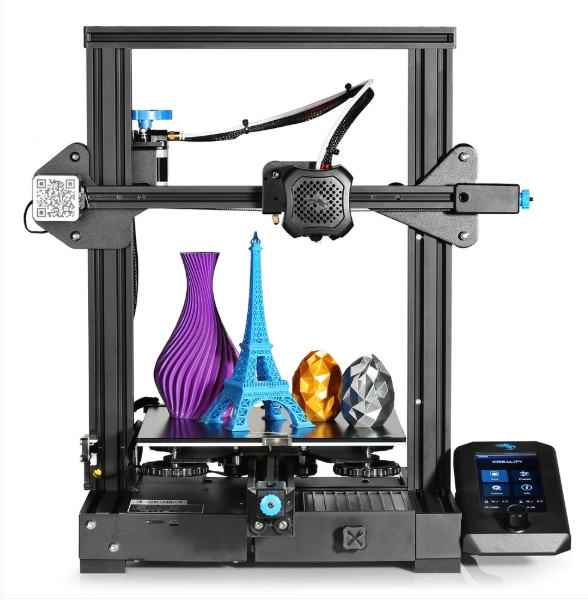

Many hobbyists start with an FDM printer like the Creality Ender 3. This printer is renowned for its reliability and ease of use. Users often print functional items such as custom brackets, replacement parts, or even household gadgets like phone stands and organizers.

Resin Printing (SLA, DLP, LCD)

- How It Works: Resin printers use a liquid photopolymer that is cured by UV light. SLA printers use a laser to cure the resin point-by-point, while DLP and LCD printers cure entire layers at once.

- Pros:

- Produces highly detailed prints with smooth surfaces

- Excellent for intricate models, miniatures, jewelry, and detailed prototypes

- Cons:

- Resin is messy and may release fumes, requiring proper ventilation and safety gear

- Post-processing (washing and additional UV curing) is necessary

- Typically more expensive than FDM systems

Real-World Example:

For artists and miniature enthusiasts, resin printers like the Anycubic Photon Mono offer exceptional detail. Model makers often use these printers to create highly detailed figurines or custom jewelry molds that demand fine detail and a smooth finish.

D. Basic Concepts Explained

- Filament: The plastic material (e.g., PLA, ABS) used in FDM printing. Each type of filament offers different characteristics in terms of strength, flexibility, and heat resistance.

- Resin: The liquid material used in resin printers, which cures into solid form when exposed to UV light.

- Nozzle: The part of an FDM printer through which the melted filament is extruded. The size of the nozzle influences both the resolution and speed of your prints.

- Build Plate/Bed: The surface where your object is printed. Ensuring proper adhesion between the print and the bed is crucial for success.

- Layer Height: The thickness of each layer, usually measured in millimeters. Smaller layer heights yield finer details but increase printing time.

- Infill: The internal structure that provides strength to your printed object. Adjusting the infill density impacts both the durability and weight of the finished product.

- Slicer Software: Programs that convert your 3D model into G-code, which instructs the printer on movements, temperature settings, and extrusion details.

- G-code: The numerical language that directs the printer’s operations.

- Bed Leveling: A critical process to ensure the build plate is perfectly flat. Proper leveling is key to preventing print failures and ensuring even layers.

II. Choosing the Right 3D Printer: A Strategic Approach

A. Define Your Needs and Goals for Purchasing Your First 3D Printer

Before making a purchase, reflect on how you plan to use your printer. Here are some questions to guide you:

- What do you plan to print?

- Example: If you’re interested in printing prototypes or mechanical parts, an FDM printer is typically best.

- Example: For intricate miniatures or detailed jewelry, a resin printer might be the better choice.

- What level of detail is necessary?

- Example: High-resolution miniatures may require the precision of resin printing, whereas larger, functional parts can often be printed adequately with an FDM printer.

- What is your budget?

- Entry-level models offer basic functionality; mid-range printers provide improved features and quality; expert-level machines are suited for professionals who demand top performance.

- What space do you have available?

- Consider the printer’s footprint and any necessary ventilation, especially for resin printers.

- How much time are you willing to invest in learning and maintenance?

- Some printers require more frequent calibration and upkeep than others.

B. Budget Considerations

- Entry-Level ($100-$300):

Ideal for beginners. These printers provide a basic set of features and decent print quality, perfect for testing the waters of 3D printing. - Mid-Range ($300-$1000):

Suitable for serious hobbyists. These printers generally offer enhanced features like auto bed leveling, larger build volumes, and more consistent performance. - Expert-Level ($1000+):

Designed for professionals or enthusiasts who require high precision, reliability, and advanced functionalities.

C. Printer Type: FDM vs. Resin

- FDM Printers:

- Best for larger prints and functional parts.

- Offer a broader selection of materials and are typically easier to maintain.

- Real-World Example: A DIY enthusiast might choose an FDM printer to create custom mounts for home automation devices.

- Resin Printers:

- Ideal for producing highly detailed models such as miniatures or intricate design pieces.

- Require careful handling of materials and additional post-processing steps.

- Real-World Example: A jewelry designer could use a resin printer to craft detailed wax models for lost-wax casting.

D. Printer Specifications to Consider when Purchasing Your First 3D Printer

- Build Volume:

The maximum size of the object you can print. Larger build volumes allow for bigger projects but may come at a higher cost. - Layer Resolution:

The minimum thickness of each layer. A lower value means higher detail but also longer print times. - Print Speed:

The speed at which the printer can deposit material. Faster speeds can improve productivity but may affect quality. - Heated Bed:

Essential for printing materials like ABS or PETG, which require a stable temperature to prevent warping. - Auto Bed Leveling:

Many modern printers offer automated bed leveling, making setup easier and reducing the chance of print failure. - Connectivity Options:

Look for printers that offer USB, SD card, or Wi-Fi connectivity for easy file transfers. - Open Source vs. Proprietary:

Open-source models often benefit from a robust community and easier customization, while proprietary models may offer streamlined user experiences and dedicated customer support. - Warranty and Support:

Choose a manufacturer known for reliability and responsive customer service. This can be invaluable, especially if you’re just starting out.

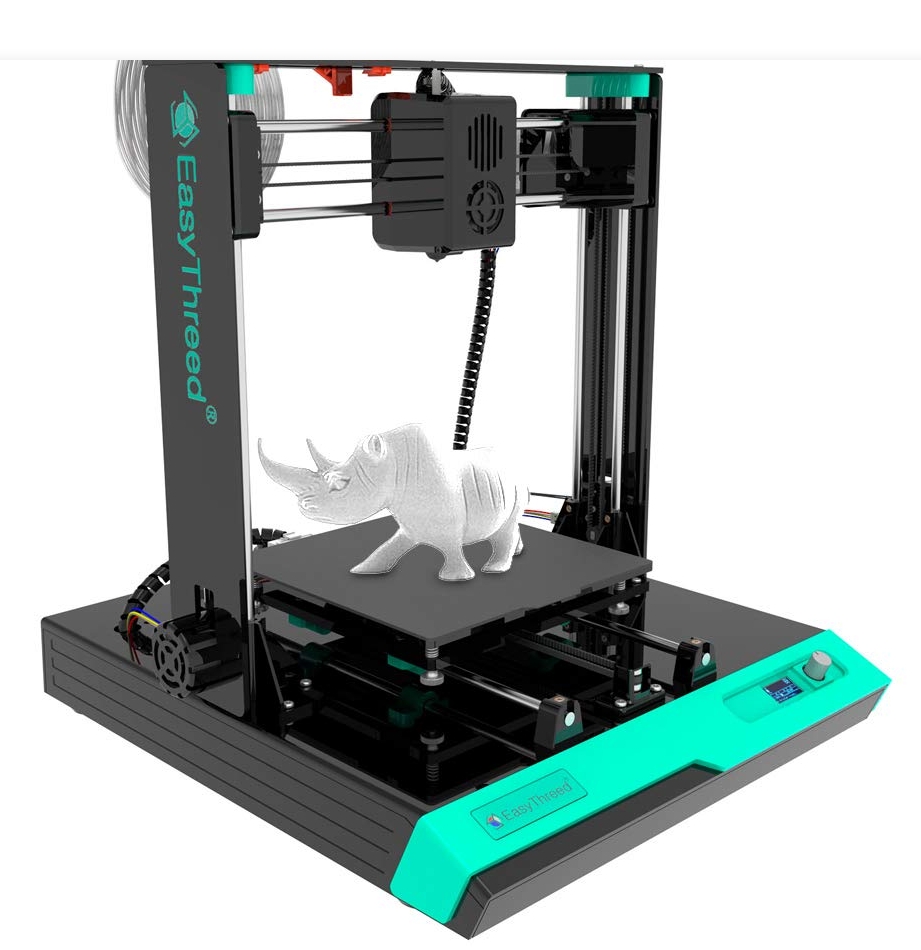

III. Printer Recommendations: A Curated Selection towards Purchasing Your First 3D Printer

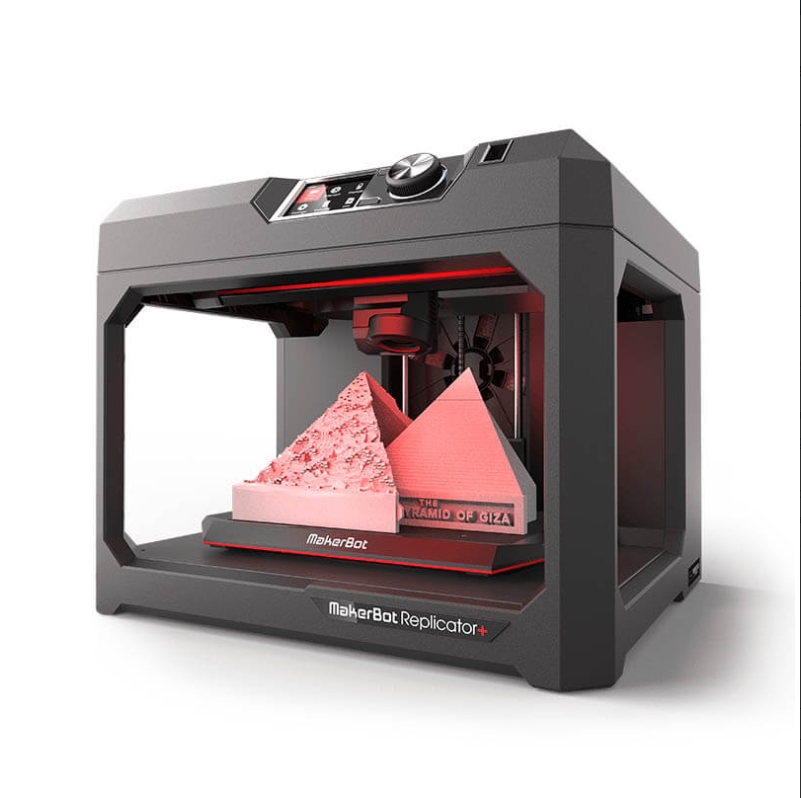

When selecting a printer, consider models that have proven their reliability through user reviews and community feedback. For example:

- For Beginners (FDM):

- Creality Ender 3: Widely recognized for its affordability and ease of use, making it an excellent entry point for those new to 3D printing.

- Real-World Example: Hobbyists have used the Ender 3 to print everything from household gadgets to replacement parts for appliances.

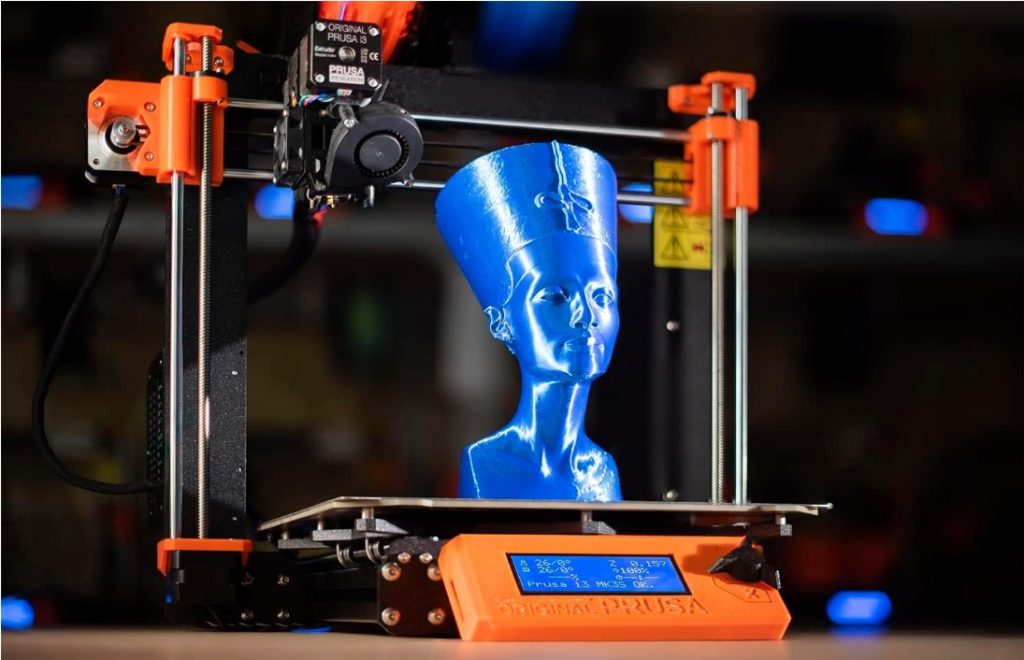

- For Mid-Range Users (FDM):

- Prusa i3 MK3S: Known for its advanced features, such as auto bed leveling and quiet operation. It’s a favorite among serious hobbyists.

- Real-World Example: Makers often rely on the Prusa for rapid prototyping of parts for DIY projects or small-scale manufacturing.

- For Detailed Work (Resin):

- Anycubic Photon Mono: A popular choice for resin printing due to its balance of quality and price.

- Real-World Example: Miniature painters and jewelry designers appreciate its ability to produce models with high surface detail and smooth finishes.

IV. Essential Accessories: Equipping Your Workspace

A well-equipped workspace can greatly enhance your 3D printing experience. Here are some must-have accessories along with practical examples:

- Filament/Resin:

- Start with PLA for FDM printers due to its ease of use and low warping characteristics, or standard resin for resin printers.

- Real-World Example: Beginners often opt for PLA to print simple items like keychains or phone stands, gradually experimenting with more specialized materials.

- Spatula or Print Removal Tool:

- Used for safely removing prints from the build plate without causing damage.

- Real-World Example: When printing a delicate figurine, a thin, flexible spatula helps detach the print without disturbing the fine details.

- Flush Cutters:

- Ideal for snipping away support structures or excess filament.

- Real-World Example: After printing a complex model with overhangs, flush cutters are used to clean up the areas where supports were necessary.

- Sandpaper and Files:

- For post-processing prints to smooth out layer lines and refine details.

- Real-World Example: A hobbyist might sand a printed phone case to achieve a polished, professional look.

- Isopropyl Alcohol (IPA):

- Essential for cleaning resin prints and ensuring the build plate is free from oils or residues.

- Real-World Example: After curing a resin print, a rinse in IPA helps remove any uncured resin, preparing the model for additional finishing work.

- Safety Gear (Glasses and Gloves):

- Particularly important for resin printing, where chemicals can be hazardous.

- Real-World Example: When working with UV-curable resins, wearing gloves and safety glasses prevents skin contact and eye irritation.

- Ventilation System:

- Ensures that fumes, especially from resin printing, are properly vented from your workspace.

- Real-World Example: A dedicated room with an air purifier or extraction fan can significantly reduce the risk of inhaling harmful fumes during prolonged printing sessions.

- Filament Storage Solutions:

- Keep filament dry and free from dust using airtight containers or dry boxes.

- Real-World Example: Users in humid environments often invest in dehumidifiers or sealed storage boxes to maintain filament quality and prevent printing issues.

V. Learning Resources: Expanding Your Knowledge before Purchasing Your First 3D Printer

Embarking on your 3D printing journey is easier with a wealth of online resources and communities:

- YouTube Channels:

- Teaching Tech, Makers Muse, CNC Kitchen, and 3D Printing Nerd offer tutorials, reviews, and troubleshooting tips that cater to both beginners and advanced users.

- Real-World Example: Many users follow step-by-step video guides to set up their printers, adjust settings, and perform routine maintenance.

- Online Model Repositories:

- Websites like Thingiverse, MyMiniFactory, and Printables provide thousands of free and paid 3D models to experiment with.

- Real-World Example: If you need a replacement part for a household appliance, you might find a ready-made design on these platforms, saving time and money.

- Discussion Forums and Social Media Groups:

- Communities on Reddit (e.g., r/3Dprinting and r/resinprinting) and dedicated forums offer invaluable peer support and advice.

- Real-World Example: When encountering a persistent print failure, many hobbyists turn to online communities to share experiences and find solutions.

- Manufacturer and Vendor Resources:

- Many 3D printer manufacturers maintain forums, blogs, and customer support channels that provide specific guidance on troubleshooting and optimizing your device.

VI. Tips for Beginners: Embarking on Your 3D Printing Journey

A. Start Small and Simple before Purchasing Your First 3D Printer

- Begin with Basic Projects:

- Print simple objects such as keychains, coasters, or phone stands. These projects help you understand printer mechanics, calibration, and basic post-processing.

- Real-World Example: Many new users start by printing a “calibration cube” to fine-tune printer settings before attempting more complex models.

B. Master Essential Techniques

- Bed Leveling:

- A perfectly leveled bed is crucial. Spend time learning the manual or automated bed leveling process on your printer.

- Real-World Example: Users who neglect bed leveling often experience warping or failed prints; mastering this process early on can save time and frustration.

- Experiment with Settings:

- Tweak layer height, print speed, infill, and temperature settings to see how they affect print quality.

- Real-World Example: If you’re printing a mechanical part, increasing infill density can improve strength, while reducing layer height may be key when printing a detailed figurine.

C. Embrace the Community

- Ask for Help:

- The 3D printing community is known for its friendliness and willingness to assist newcomers. Don’t hesitate to ask questions on forums or social media groups.

- Real-World Example: When facing an unusual error, a quick post on a community forum might reveal that others have experienced and solved the same issue.

D. Maintain Your 3D printing Equipment

- Regular Maintenance:

- Keep your printer clean, perform routine checks, and replace worn parts as needed to extend its lifespan.

- Real-World Example: Periodic cleaning of the nozzle and checking for loose bolts can prevent print failures and ensure consistent performance over time.

E. Prioritize Safety

- Follow Safety Guidelines:

- Always use appropriate safety equipment—especially when working with resins—and ensure your workspace is well-ventilated.

- Real-World Example: Establishing a dedicated printing station with a fume extractor not only protects your health but also creates an environment optimized for high-quality printing.

By following this expanded guide, you will not only understand the fundamentals of 3D printing but also gain practical insights into selecting the right printer when purchasing your first 3D printer, setting up a productive workspace, and leveraging community resources for ongoing learning. With real-world examples and step-by-step tips, you’re now well-equipped to embark on your 3D printing journey. Also, check out this cool post: Tool ideas for DIY Happy printing!